Lepower shares attended the high-tech LED packaging change seminar

2016-09-12

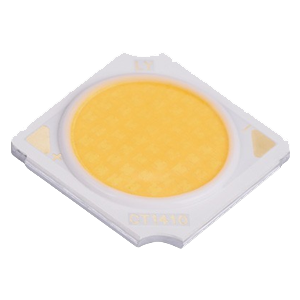

Throughout the development of LED light source products, high power, high lumen output has always been the main melody of market demand, the development of Flip LED process will also mainly focus on high power and high optical density output devices, while the development direction will gradually transition to flip-chip on PCB(FCOB) and standardized optical components.

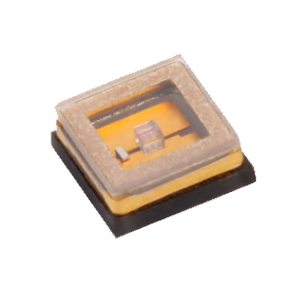

As a pioneer of inverted light source, Liyang shares are in sync with international first-line brands in the manufacturing process and equipment of inverted LED. In the base plate brush solder paste manufacturing process, Liyang adopts the world's leading 3D automatic printing technology, eutectic welding, high efficiency and strong reliability; At the same time, in terms of monitoring equipment, it is equipped with an advanced automatic X-RAY cavity rate monitor to monitor the entire production of products, and the quality is greatly improved.

On September 9, the packaging change seminar sponsored by Gaogong LED was successfully held in Shenzhen Qingqing World, and Yin Shunpeng, deputy general manager of Liyang Shares, shared and discussed the "Analysis of the new generation of LED packaging technology based on the flip process" with industry leaders and elites.

The emergence of inverted light source meets the market's demand for LED light source with high performance, high quality, high light efficiency and high cost performance, but there are still some difficulties in the popularity of inverted LED, which is mainly reflected in the following four aspects:

1, the upstream chip brand and size choice (relatively formal) less;

2. The production capacity and yield of flip chips need to be further improved;

3, flip LED technology is currently in the middle and high power products and integrated packaging advantages, in the application of low power, cost competitiveness is not very strong;

4, inverted LED subvert the traditional LED process, from the chip to the package, the production and testing equipment requirements are higher. Just take the package to say that the front-end equipment cost that can do flip chips will certainly increase a lot, which sets the threshold, so that some enterprises can not really use this technology.

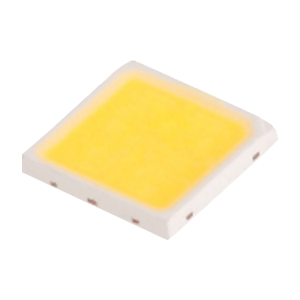

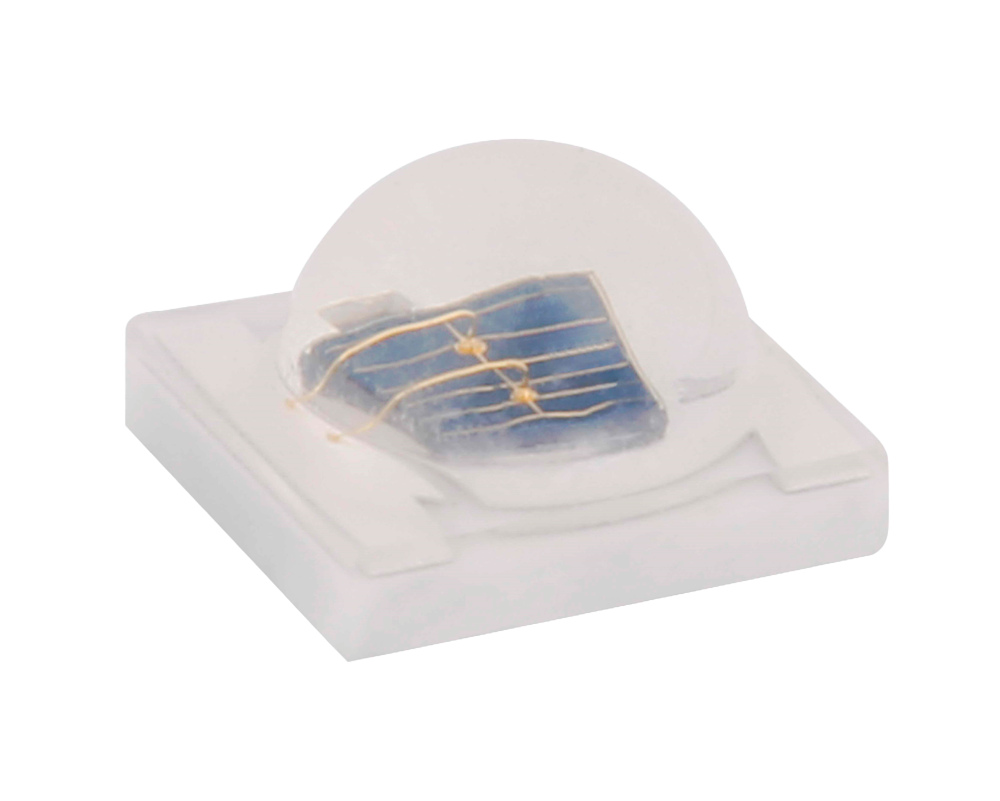

At present, the flip LED production line of Liyang shares has been successfully mass produced, with stable quality and introduced into various products, which will win the opportunity for the future development of the company. Such as backloading EMC series FE30/FE35, the product performance is superior, cost-effective, the four characteristics of the product itself has achieved the king style of this series of products.

First, the super reliability dead lamp rate is close to zero. FE30/FE35 gold-free wire package completely eliminates a variety of reliability problems caused by the key alloy wire, and the dead lamp rate of the lamp is greatly reduced;

Second, reduce the cost of the lighting system. The lamp body of FE30/FE35 light source is smaller, the power is larger, the effect is better, the design space is larger, and the system cost of the lamp is greatly reduced;

Third, long service life. Using solder paste with thermal conductivity tens of times and insulation to connect the thermal resistance between the lens electrode and the support, improve the thermal conductivity of the LED;

Fourth, the patent Molding technology light rate greatly improved. The use of innovative structure, standard Liyang self-developed single-package lens, compared with the previous generation of flat packaging products, on the one hand to increase the light rate of 8%-10%, on the other hand to increase the front emission area, the hot channel is smoother, while easy to secondary light distribution, light efficiency is greatly improved!

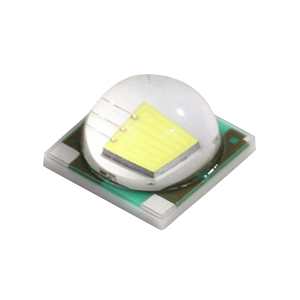

Flip products are mainly used in outdoor lighting (instead of traditional COB light source products, applied to outdoor lighting, such as: street lights, high pole lights, etc.), special lighting (instead of traditional COB light source products, applied to high-power special lighting, such as: car lights, stage lights, projectors, etc.) and many other fields, with broad prospects.