Lepower Shares: Enjoy the affordable luxury of high efficiency light pearl source, starting from FE30/FE35

2016-07-15

Technological innovation and market demand are the two major powers for the development of the LED industry. Throughout the development of LED packaging in China, it has experienced from the early pin-type LED devices, patch type printed circuit board (PCB) structure, polyphthalamide (PPA), polyadimethylate terephthalate (PCT) to the current aluminum nitride ceramic structure, high-power integrated on-board chip packaging (ChipOnBoard). COB), thermosetting epoxy resin (EMC) structure LED devices, various types of crystal coating and other different forms of packaging.

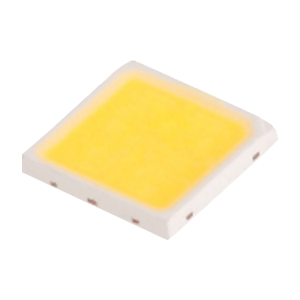

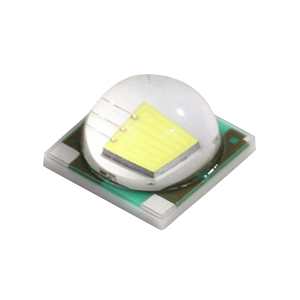

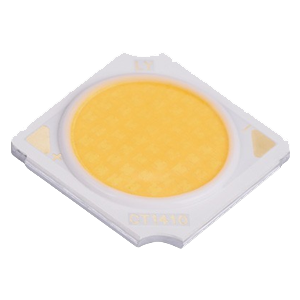

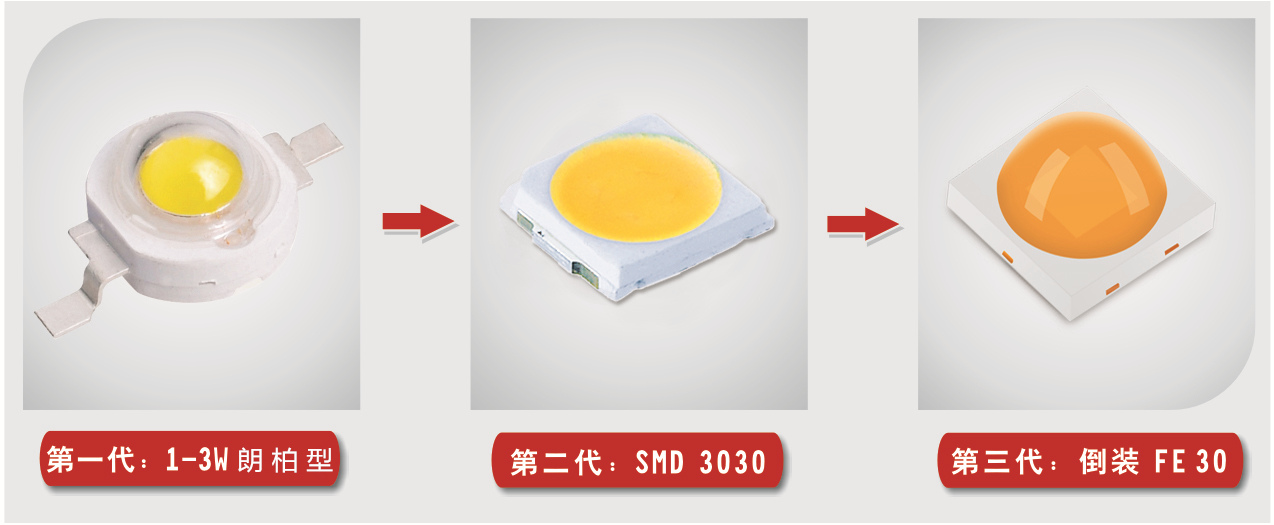

As a leader in the LED packaging industry, Shenzhen Liyang Optoelectronics Co., LTD. (hereinafter referred to as "Liyang Shares") has witnessed the transformation and technological innovation of LED light source products since its establishment in 2008. In terms of high-power lamp beads, the product development of Liyang shares has mainly experienced three stages: from the earliest 1-3W Lambert lamp beads, to SMD2835/SMD3030 patch lamp beads, and now the flip FE30/FE35 series, the chip of the product is getting smaller and smaller, more and more reliable, and more and more cost-effective.

The birth of the FE30/FE35 series is based on the market demand for higher power and higher brightness. At the beginning of product development, the market positioning of FE30/FE35 has been very clear: replace the traditional 1W imitation lumen products, upgrade the flat EMC3030 products, ceramic substrate 3030/3535 products, replace similar XPG series products, and enter the market through super stability and ultra-high cost performance.

Understand the inversion, into the Liyang

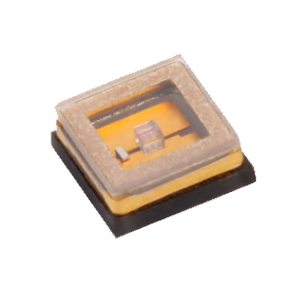

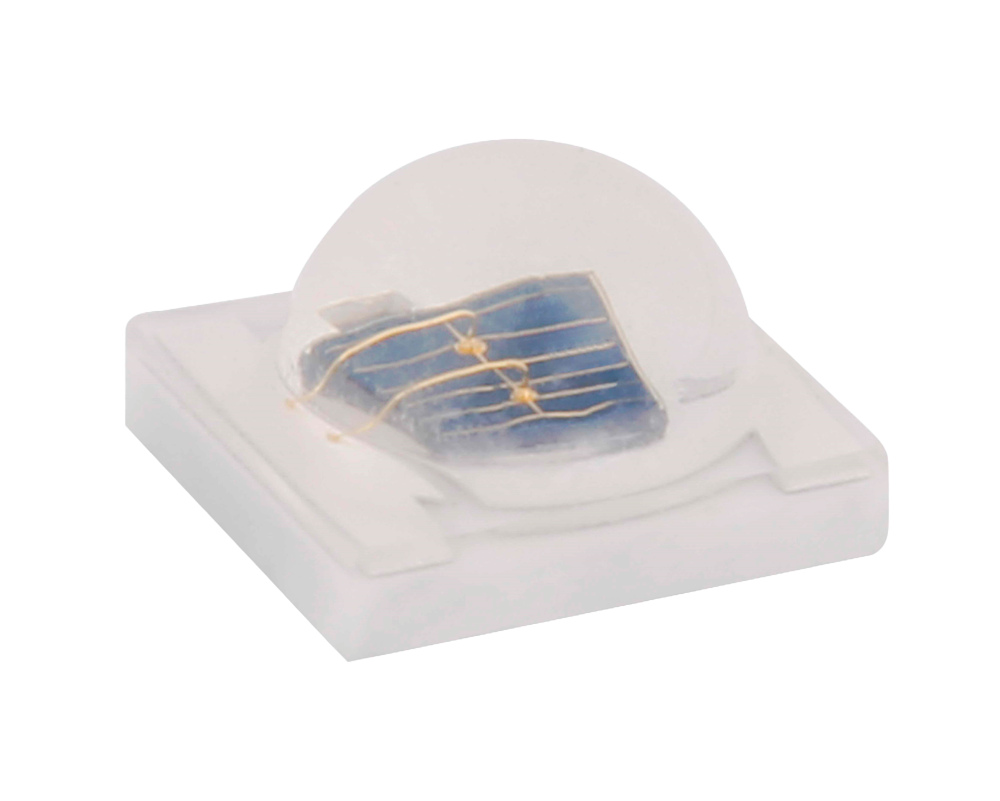

Why is FE30/FE35 an affordable luxury lamp bead? Before introducing the powerful performance of FE30/FE35 products, we have to say that the flip packaging process. Flip LED, also known as Flip chip LED, is based on flip LED chip technology, using solder paste reflux process or eutectic process, the LED chip and the support are connected to achieve gold-free packaging, which completely eliminates the leakage, flicker, dead light and other reliability problems caused by gold wire. The flip LED packaging process subverts the traditional LED process, from the substrate printing solder paste, to the wafer consolidation, and then to reflow welding, the input cost is higher, and the process is more strict. This is mainly reflected in the solder paste printing requirements are more accurate, reflow process requirements are more stable, solid precision requirements are higher, but also need to increase professional monitoring equipment, this demanding requirements, so that a large number of enterprises can not access to this core technology. This has also LED to the current market flip LED light source products mixed, many flip products due to poor chip performance, raw material quality, coupled with the production process and production equipment can not meet the requirements, making the product produced low price, poor reliability, affect the image of flip products in the eyes of customers.

As the pioneer of flip light source, Liyang shares in the flip process manufacturing process and equipment with the international first-line brand synchronization, in the substrate printing solder paste manufacturing process, Liyang shares adopted the world's leading 3D automatic printing technology, eutectic connection, good firmness, strong stability, while in the monitoring equipment, Liyang is equipped with expensive X-RAY cavity rate monitor to monitor product production throughout the process, and the quality is greatly improved. In April 2016, Liyang Shares became the technical research project bearer of Shenzhen Science and Technology Innovation Commission "Key technology research and development of high-power LED multi-core integrated light source module based on flip process", and received strong support from government departments in terms of technology research and development funds and related policies.

The powerful performance of FE30/FE35 series products is mainly reflected in the following aspects.

Super reliability, zero dead lamp rate

FE30/FE35 series adopts no gold wire package, and adopts imported EMC bracket, which has the advantages of high light efficiency, long life, low thermal resistance, small size, flexible size and easy application. EMC device applications offer a seamless replacement and significant advantages over traditional formal SMD LED devices. First of all, the chip electrode of the formal SMD device is located on the luminous surface, and the bonded metal lead is located above the luminous surface, which absorbs the light from the chip and reduces the luminous efficiency of the LED. The flip chip electrode used by the EMC device is located at the bottom of the chip, which does not affect the surface light, and adopts the leadless package to directly avoid the absorption of the metal lead to the light. The optical surface of the chip is transparent sapphire, whose refractive index is between GaN and the packaging adhesive, and the light matching with the packaging adhesive is better, and the light output efficiency is higher. Secondly, the formal SMD LED bonding lead is prone to problems such as virtual welding, surge impact, insufficient resistance to high current, and stress fracture caused by thermal mismatch with packaging adhesive, which is one of the weakest links in the reliability of LED devices, and the dead lamp rate of 98% in formal products is caused by gold wire breakage. The breakage of the gold wire will accelerate the current load of other parallel gold wires at work, resulting in an increase in the instability factor of the product and an increase in the dead lamp rate, which is mainly due to the structural decision of the formal product, FE30/FE35 reduces the welding process, improves the production efficiency, and eliminates a variety of reliability problems that may be caused by the bonding lead.

Liyang FE30/FE35 series, products have obtained LM-80 test report, in line with ANSI or ERP spectrophotometric color separation standards.

Supports ultra-large current input, up to 1A

In order to concentrate resources on the development of high-power devices, the development idea of Liyang power devices is "high-density LED technology", which is commonly known as high power and small size. The so-called high power means that the power and light efficiency are increased as much as possible under the same package size, so that although the cost of a single package does not change much, it can greatly reduce the cost of system integration.

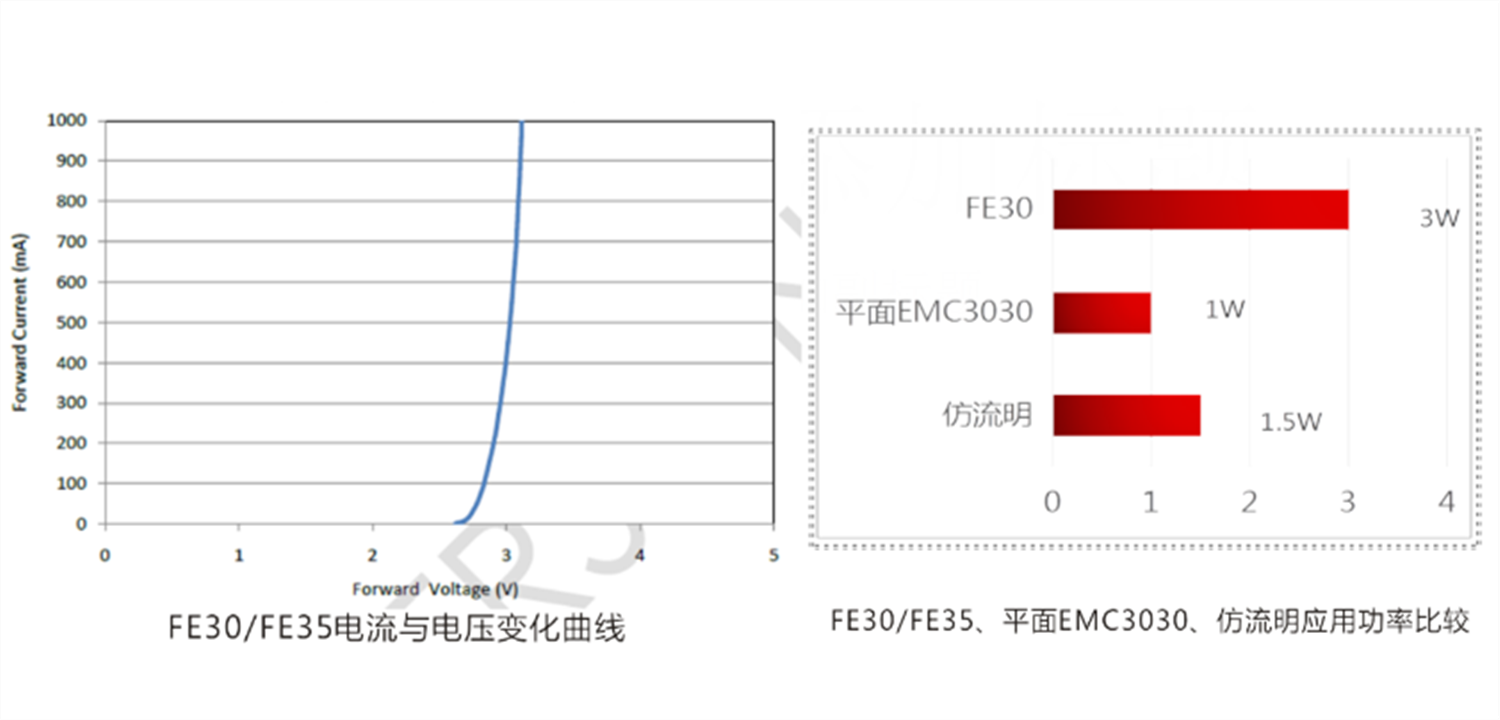

FE30/FE35 series is designed to uphold this concept, support 1A large current input, maximum power 3W, luminous flux up to 400lm, much higher than the traditional imitation lumen products and flat EMC3030 series products. At present, the market imitation lumen products support the maximum current input of 550ma, the maximum power of 1.5W, flat EMC3030 products support the maximum input current of 350ma, the maximum power of only 1W. This makes FE30/FE35 series products in practical applications compared to flat EMC3030 series products or imitation lumen products, higher illumination and better lighting effect.

Super hot channel, product life greatly improved

Due to the different solidification methods, FE30/FE35 is more than 10 times the hot channel of traditional formal products. FE30/FE30 series uses solder paste solidification, thermal conductivity is 25-30W/(M*K), while traditional formal products mostly use high-conductivity silver adhesive solidification, thermal conductivity is only 1-2W/(M*K), which effectively solves the problem of light source thermal conductivity, makes the product hot channel smoother, greatly improve the service life!

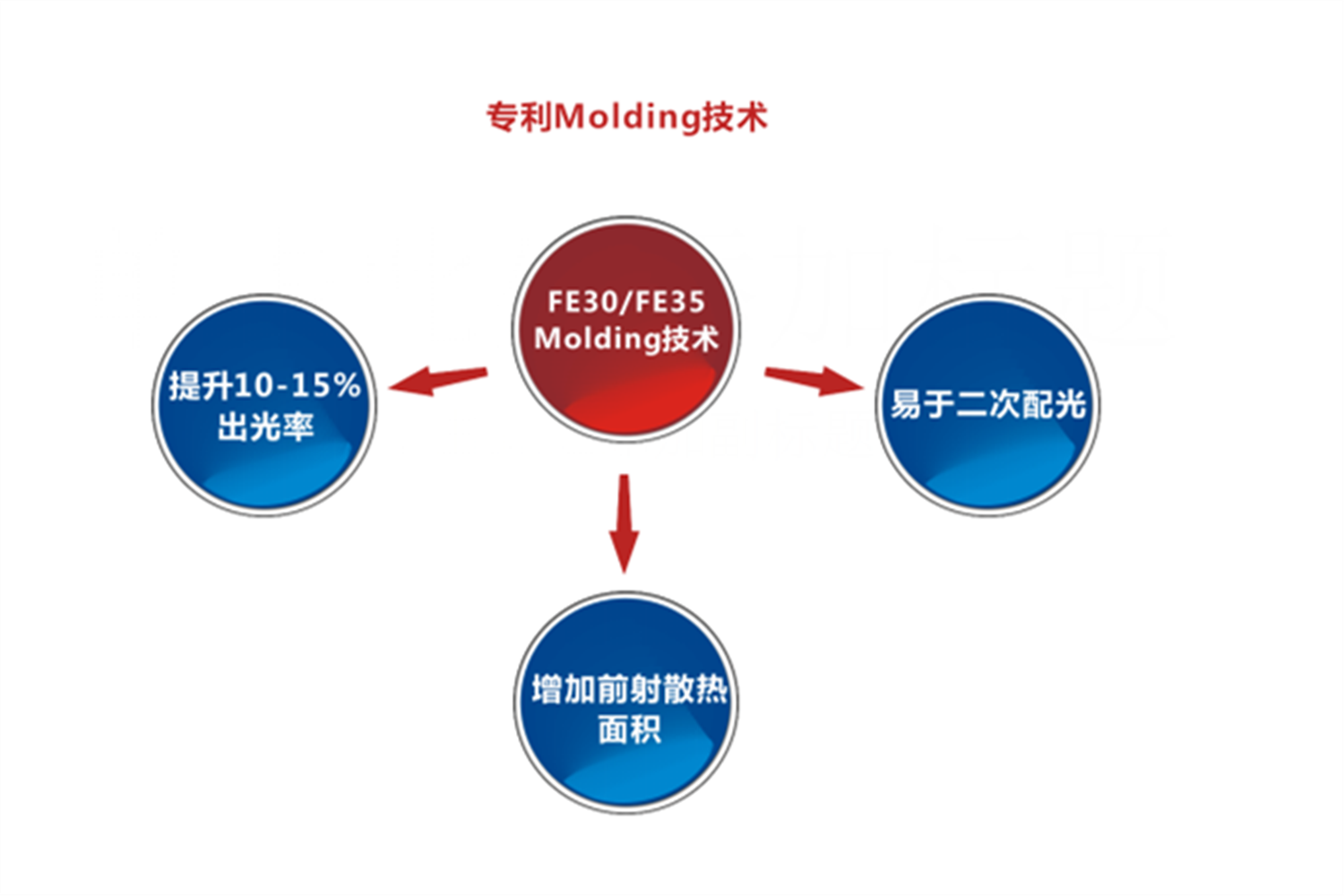

Patented Molding technology, light Angle can be customized

FE30/FE35 series with independent innovative structure, after precision optical design, can accept a small Angle of light customized, the minimum Angle of up to 30 degrees, which greatly meet some special areas of strong directional lighting needs. It is almost impossible to complete in the traditional formal wear products, taking the imitation lumen products as an example, the minimum support Angle is only 60 degrees. At the same time, FE30/FE35 patent Molding design, compared with the previous generation of flat packaging products, improve the light output rate by 10%-15%, at the same time, due to the increase of the front shooting area, make the product hot channel smoother, easier to secondary light distribution.

Market, technology and cost are mutually reinforcing and influencing each other. Technological progress has spawned a new application market, and cost reduction has promoted the pace of technology penetration into emerging markets, the rise of emerging markets and put forward higher requirements for technology and costs, this dependency on the LED industry is no exception, and Liyang FE30/FE35 series is born in this environment, deep cultivation technology, To achieve the ultimate in technology and cost, to help enterprises become the king of the high-power LED market segment, from the Red Sea market to the vast blue ocean market, is part of the strategic planning of Liyang shares at this stage.